Benefits of Line Graining Services for Metal Fabricators

Introduction

In the competitive world of metal fabrication, it is essential to deliver products that not only meet but exceed customer expectations. As a metal fabricator, providing top-notch line graining services can set your business apart from the competition. In this article, we will explore the numerous benefits of line graining services and how Cresco Custom Metals can help you achieve outstanding results.

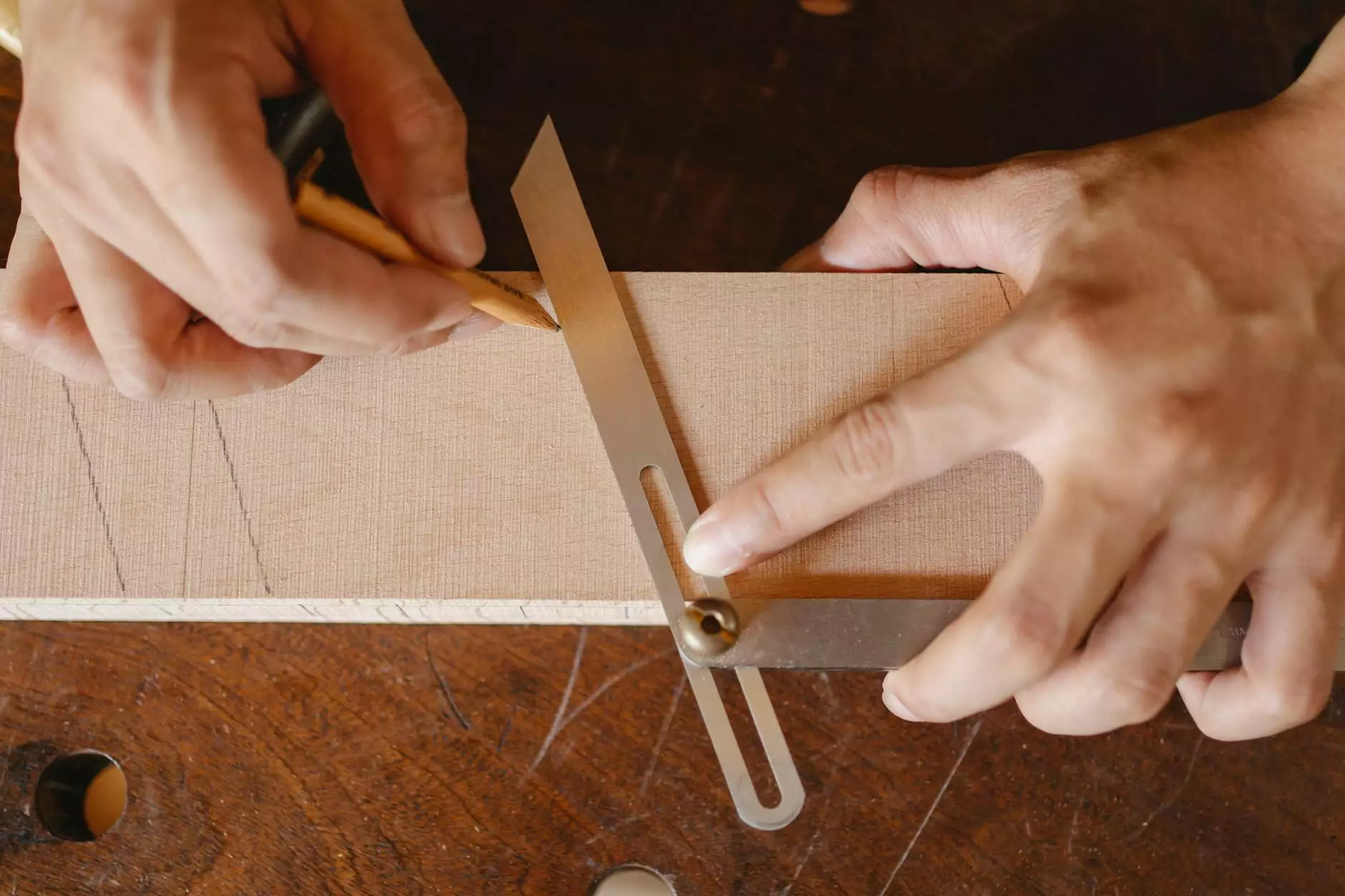

Enhanced Appearance

Line graining, also known as grain finishing, is a technique used to create a decorative and uniform finish on metal surfaces. This process involves using abrasive belts or brushes to create parallel lines on the material's surface, resulting in a sleek and visually appealing look. By opting for line graining services, metal fabricators can enhance the overall appearance of their products, giving them a sophisticated and professional finish.

Improved Functionality

Line graining not only enhances the aesthetics of metal products but also improves their functionality. This process can be used to remove imperfections such as burrs, sharp edges, or rough surfaces, making the final product safe and user-friendly. Additionally, line graining assists in minimizing surface glare and reflection, making it an ideal choice for applications where light reflection could be a concern.

Increased Durability

Metal fabricators aim to provide their customers with durable and long-lasting products. Line graining plays a crucial role in enhancing the durability of metal parts by reducing the risk of corrosion and wear. The consistent and controlled abrasion during the line graining process removes contaminants and creates a barrier that helps protect the metal surface from external elements. This, in turn, extends the lifespan of the products, ensuring customer satisfaction and repeat business.

Customizability

Every metal fabrication project is unique, and line graining offers endless possibilities for customization. With various grit options, direction choices, and patterns, metal fabricators can achieve the desired texture and finish on their products. Whether it's a smooth, fine-grained appearance or a more rugged and textured finish, line graining allows for customization that caters to specific customer preferences.

Seamless Integration

Line graining can be seamlessly integrated into the overall metal fabrication process, adding value and efficiency. By collaborating with a trusted partner like Cresco Custom Metals, metal fabricators can streamline their production line and reduce lead time. The experts at Cresco Custom Metals can provide line graining services tailored to your specific project requirements, ensuring a smooth and timely completion of your orders.

Industry Compliance

Operating in a highly regulated industry, metal fabricators must adhere to specific standards and certifications. Line graining helps meet these compliance requirements by achieving surface finish specifications outlined by industry standards. Compliance with these standards is critical for metal fabricators to establish trust, attract new clients, and maintain a reputable position in the market.

Conclusion

Line graining services offer a multitude of benefits for metal fabricators. From enhancing the appearance and functionality to increasing durability and customization options, line graining is an essential process that adds value to metal products. By partnering with Cresco Custom Metals, metal fabricators can benefit from their expertise in line graining services and deliver outstanding results that surpass customer expectations. Invest in line graining services and stay ahead in the competitive metal fabrication industry.