CNC Machining China Factory: Unlocking Precision and Efficiency in Metal Fabrication

The world of manufacturing has undergone a significant transformation over the years. Among the advancements, CNC machining stands out as a beacon of precision and innovation, particularly in the realm of metal fabrication. Choosing the right partner for your manufacturing needs is crucial, and this is where a CNC machining China factory can provide unmatched advantages.

What is CNC Machining?

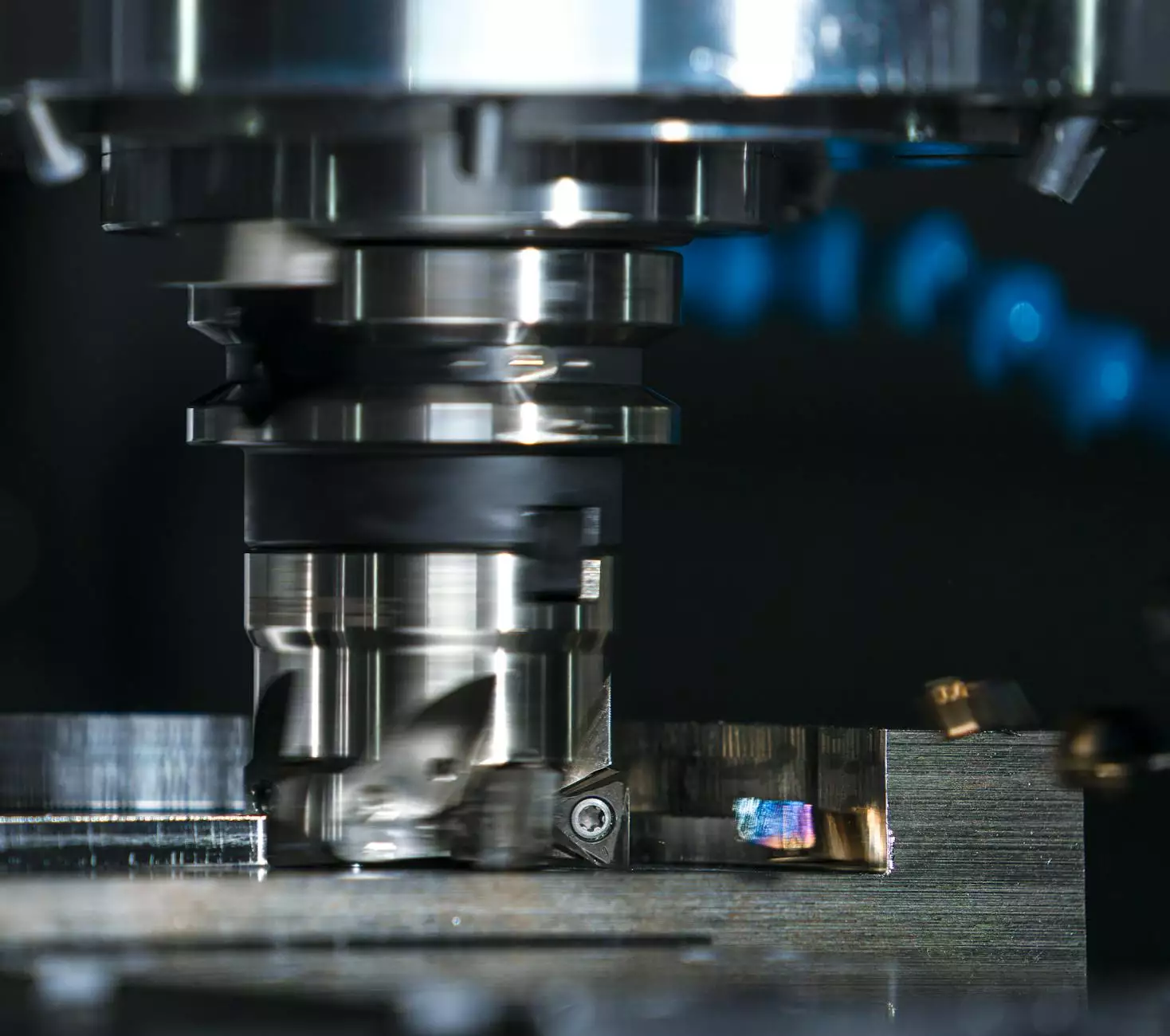

CNC, or Computer Numerical Control, machining is a process that utilizes computer software to control machine tools. These machine tools are responsible for performing tasks such as drilling, milling, and turning of materials. Through the CNC process, manufacturers gain the capability to produce incredibly precise components with intricate designs and superior quality.

The Rise of CNC Machining in China

China has rapidly emerged as a global leader in manufacturing, and its prowess in CNC machining is pivotal to this rise. Gripped by the tech boom and expansive workforce, CNC machining China factories have revolutionized the industry, providing solutions that are both cost-effective and high-quality. This growth is driven by several factors:

- Advanced Technology: Chinese manufacturers leverage state-of-the-art CNC machines and technology, ensuring that they remain competitive on the global stage.

- Skilled Workforce: With a large pool of skilled engineers and technicians, China has the human resources necessary to operate sophisticated CNC machinery.

- Cost Efficiency: Lower labor costs in China mean that businesses can access high-quality CNC machining at significantly reduced prices.

- Rapid Turnaround Times: The efficiency of operations in Chinese factories ensures that projects are delivered quickly, which is crucial for businesses needing to adhere to tight deadlines.

Benefits of Choosing a CNC Machining China Factory

Engaging with a CNC machining China factory presents numerous benefits for businesses in need of metal fabrication services. Here are several compelling reasons to consider:

1. High Precision and Quality

One of the most notable advantages of CNC machining is the extraordinary level of precision it offers. Machines can be calibrated to produce parts within a very tight tolerance range. This level of quality is paramount in industries such as aerospace, automotive, and medical devices where minor errors can lead to catastrophic failures.

2. Customization and Flexibility

CNC machining allows for customized solutions tailored to specific needs. Whether it's unique dimensions or specific material properties, a CNC machining China factory can accommodate nearly any request, enabling companies to innovate and differentiate their products in the market.

3. Scalability

As your business grows, so do your needs. CNC machining is exceptionally scalable; whether you're producing small batches or large volumes, the manufacturing processes can be adjusted accordingly without sacrificing quality or increasing lead times.

4. Cost-Effectiveness

When compared to traditional manufacturing methods, CNC machining is often more cost-effective. The initial investment in CNC machinery can be high, but the long-term savings achieved through efficiency, reduced waste, and lower labor costs effectively outweigh the expenses.

Industries Benefiting from CNC Machining

Several industries benefit significantly from the capabilities of a CNC machining China factory. These include but are not limited to:

- Aerospace: Precision components that withstand rigorous operational conditions.

- Automotive: Parts manufacturing that require high durability and security standards.

- Medical: Production of sterile devices and tools with exact specifications.

- Consumer Electronics: Parts for devices that require intricate designs and durability.

- Industrial Equipment: Components that need to be robust, reliable, and efficient.

How to Choose the Right CNC Machining China Factory

Choosing the right CNC machining China factory requires thorough consideration. Here are some essential factors to weigh:

1. Quality Assurance Processes

Ensure the factory has robust quality assurance protocols in place. Certifications such as ISO 9001 can be indicators of a company’s commitment to quality.

2. Experience and Expertise

Look for suppliers with extensive experience in CNC machining. A factory that has a proven track record in your specific industry is more likely to meet your requirements accurately.

3. Technology and Equipment

Examine the technology and machinery used by the factory. Advanced CNC machines improve efficiency and precision, significantly impacting your final product's quality.

4. Customer Support and Service

A good manufacturing partner should provide excellent customer service. Ensure they are responsive and willing to work collaboratively throughout the process.

5. Cost Competitiveness

While cost is a vital factor, it should not be the sole consideration. Look for a balance between quality and price. The cheapest option may not always provide the best value in the long run.

Future Trends in CNC Machining

The future of CNC machining is vibrant and holds promising developments:

1. Automation and IoT Integration

The integration of automation and the Internet of Things (IoT) will enhance the efficiency of CNC machining plants. As factories become smarter, capabilities in monitoring and predictive maintenance will enable better production workflow and reduced downtime.

2. Advanced Materials

As technology progresses, manufacturers will be able to work with advanced materials such as carbon fiber and composites. This will allow the production of lighter and stronger components that offer improved performance.

3. Sustainability Practices

Sustainability is becoming increasingly vital in manufacturing. CNC machining technology will likely focus on waste reduction and sustainable practices, attracting environmentally conscious clients.

In Conclusion

Partnering with a CNC machining China factory can be a game-changer for businesses looking to enhance their manufacturing capabilities. From high precision and customization to cost savings and scalability, the benefits are manifold. By carefully selecting a reputable factory that aligns with your specific needs, you can ensure the successful realization of your project while staying ahead of the competition.

Contact DeepMould for Your CNC Machining Needs

If you’re interested in exploring top-notch CNC machining solutions in China, look no further than DeepMould. With expert knowledge in metal fabrication and years of experience, we’re committed to delivering high-quality fabricated products tailored to your business requirements.

Let us help you unlock the full potential of your products with our cutting-edge CNC machining services. Contact us today!